1. YZ series is the up to date design electric motor with the characteristic of big overload capacity and high mechanical strength, which is specially adequate for driving all sorts of metallurgical machinery and hoisting machine or the other similar equipment. YZ series is squirrel cage type electrical motor.

2. The electrical motor can normal operate in the following environmental conditions.

(1.) Cooling medium temperature is no more than 60℃(electrical motor of metallurgy) or 40℃( hoisting motor).

(2.) The altitude is no more than 1,000 meters

(3.) Regular and obvious mechanical vibration and mechanical shock

3. The electrical motor can normally work in the following loading condition:

(1.) Regular starting and back turn

(2.) Regular electrical appliance braking and mechanical braking

4. Rated frequency: 50 Hz, rated voltage: 380V

5. Rejoining method: stator winding uses Y rejoining method when the power is 132 kilowatt or lower 132 kilowatt. The others use △ rejoining method.

| Duty | S3 | ||||||||||||||

| FC | 40% | 60% | 100% | ||||||||||||

| Item | P | U | I | n | Tst/TN | Tmax/TN | Ist/IN | η | cosΦ | P | I | n | P | I | n |

| KW | V | A | r/min | KW | A | r/min | KW | A | r/min | ||||||

| Model | 1000r/min | ||||||||||||||

| YZ112M-6 | 1.5 | 380 | 4 | 875 | 2.6 | 2.7 | 3.7 | 71 | 0.79 | 1.1 | 3 | 910 | 0.8 | 3 | 935 |

| 132M1-6 | 2.2 | 380 | 5.5 | 910 | 2.6 | 2.5 | 4.2 | 76 | 0.78 | 1.8 | 5 | 925 | 1.5 | 4 | 940 |

| 132M2-6 | 3.7 | 380 | 9 | 900 | 2.3 | 2.3 | 4 | 77 | 0.82 | 3 | 7 | 920 | 2.8 | 7 | 925 |

| 160M1-6 | 5.5 | 380 | 13 | 905 | 2.3 | 2.3 | 4 | 77 | 0.84 | 5 | 12 | 910 | 4 | 10 | 925 |

| 160M2-6 | 7.5 | 380 | 17 | 910 | 2.6 | 2.7 | 4.4 | 79 | 0.83 | 6.3 | 15 | 920 | 5.5 | 13.5 | 930 |

| 160L-6 | 11 | 380 | 24.5 | 905 | 2.4 | 2.5 | 4.3 | 79 | 0.85 | 9 | 20.5 | 920 | 7.5 | 18 | 930 |

| Model | 750r/min | ||||||||||||||

| YZ160L-8 | 7.5 | 380 | 20 | 670 | 2.3 | 2.3 | 3.4 | 76 | 0.75 | 6 | 17 | 685 | 5 | 15 | 695 |

| 180L-8 | 11 | 380 | 26 | 680 | 2.3 | 2.4 | 4.2 | 79 | 0.81 | 9 | 22 | 690 | 7.5 | 19 | 700 |

| 200L-8 | 15 | 380 | 34 | 690 | 2.7 | 2.9 | 5.1 | 82 | 0.8 | 13 | 30 | 695 | 11 | 27 | 705 |

| 225M-8 | 22 | 380 | 49.5 | 690 | 2.6 | 3.1 | 5.1 | 83 | 0.81 | 18.5 | 43 | 695 | 17 | 40.5 | 700 |

| 250M1-8 | 30 | 380 | 67 | 685 | 2.6 | 3.1 | 5.1 | 83 | 0.81 | 26 | 59 | 690 | 22 | 52.5 | 700 |

| Duty | S2 | S3 | ||||||||||

| FC | 30min | 60min | 15% | 25% | ||||||||

| Item | P | I | n | P | I | n | P | I | n | P | I | n |

| KW | A | r/min | KW | A | r/min | KW | A | r/min | KW | A | r/min | |

| Model | 1000r/min | |||||||||||

| YZ112M-6 | 1.8 | 4.7 | 840 | 1.5 | 4 | 875 | 2.2 | 6.3 | 790 | 1.8 | 4.7 | 840 |

| 132M1-6 | 2.5 | 6 | 890 | 2.2 | 5.5 | 910 | 3 | 7 | 860 | 2.5 | 6 | 890 |

| 132M2-6 | 4 | 9.5 | 880 | 3.7 | 9 | 900 | 5 | 12 | 840 | 4 | 9.5 | 880 |

| 160M1-6 | 6.3 | 14.5 | 880 | 5.5 | 13 | 905 | 7.5 | 18 | 840 | 6.3 | 14.5 | 880 |

| 160M2-6 | 8.5 | 19 | 890 | 7.5 | 17 | 910 | 11 | 26 | 840 | 8.5 | 19 | 890 |

| 160L-6 | 13 | 29 | 870 | 11 | 24.5 | 905 | 15 | 35 | 840 | 13 | 29 | 870 |

| Model | 750r/min | |||||||||||

| YZ160L-8 | 9 | 23 | 645 | 7.5 | 20 | 670 | 11 | 31 | 590 | 9 | 23 | 645 |

| 180L-8 | 13 | 30 | 660 | 11 | 26 | 680 | 15 | 36 | 635 | 13 | 30 | 660 |

| 200L-8 | 18.5 | 41 | 670 | 15 | 34 | 690 | 22 | 50 | 650 | 18.5 | 41 | 670 |

| 225M-8 | 26 | 58 | 670 | 22 | 49.5 | 690 | 33 | 76 | 640 | 26 | 58 | 670 |

| 250M1-8 | 35 | 77.5 | 670 | 30 | 67 | 685 | 42 | 95 | 645 | 35 | 77.5 | 670 |

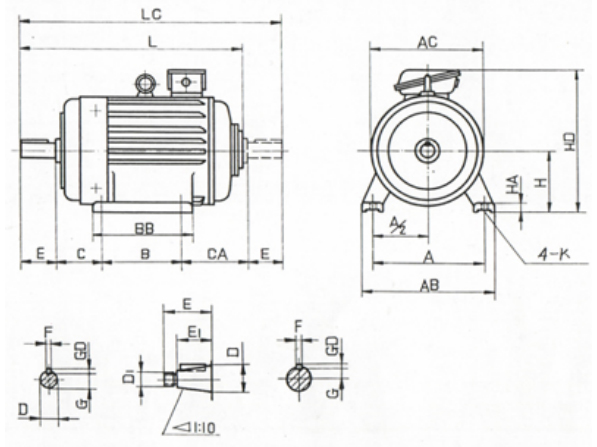

| Frame | Mounting Size | Overall Size | |||||||||||||||||||||

| H | A | A/2 | B | C | CA | K | Bolts | D | D1 | E | E1 | Key | Keyway | AC | AB | HD | BB | L | LC | HA | |||

| Size | Size | Size | Size | Size | Size | Size | Size | F(h9) | GD | F(h9) | G | ||||||||||||

| 112M | 112 | 190 | 95 | 140 | 70 | 135 | 12 | M10 | 32 | – | 80 | ﹣ | 10 | 8 | 10 | 27 | 245 | 250 | 330 | 235 | 400 | 505 | 15 |

| 132M | 132 | 216 | 108 | 178 | 89 | 150 | 38 | 33 | 285 | 275 | 360 | 260 | 495 | 577 | 17 | ||||||||

| 160M | 160 | 254 | 127 | 210 | 108 | 180 | 15 | M12 | 48 | 110 | 14 | 9 | 14 | 43 | 325 | 320 | 420 | 290 | 608 | 718 | 20 | ||

| 160L | 254 | 335 | 650 | 762 | |||||||||||||||||||

| 180L | 180 | 279 | 140 | 279 | 121 | 55 | M36×3 | 82 | 20 | 360 | 360 | 460 | 380 | 685 | 800 | 22 | |||||||

| 200L | 200 | 318 | 159 | 305 | 133 | 210 | 19 | M16 | 60 | M42×3 | 140 | 105 | 16 | 10 | 16 | 21 | 405 | 405 | 510 | 400 | 780 | 928 | 25 |

| 225M | 225 | 356 | 178 | 311 | 149 | 258 | 65 | 24 | 430 | 455 | 545 | 410 | 850 | 998 | 28 | ||||||||

| 250M | 250 | 406 | 203 | 349 | 168 | 295 | 24 | M20 | 70 | M48×3 | 18 | 11 | 18 | 25 | 480 | 515 | 605 | 510 | 935 | 1092 | 30 | ||

Once you fill in this form, we will get in touch with you shortly, assess and solve your problem in the most effective way